CAPABILITIES

Better Toolpaths with VoluMill Software

China Manufacturing Parts has manufactured sub-assembly components for a leading US based computer and printer manufacturer. The sizes ranged from miniature to 72″. China Manufacturing Parts supplied these components for 18 months, until the contract went into a rebid. With the aim to compete with suppliers on a global scale and a major nearest competitor, China Manufacturing Parts decided to find ways to cut costs, and optimize its working efficiencies.

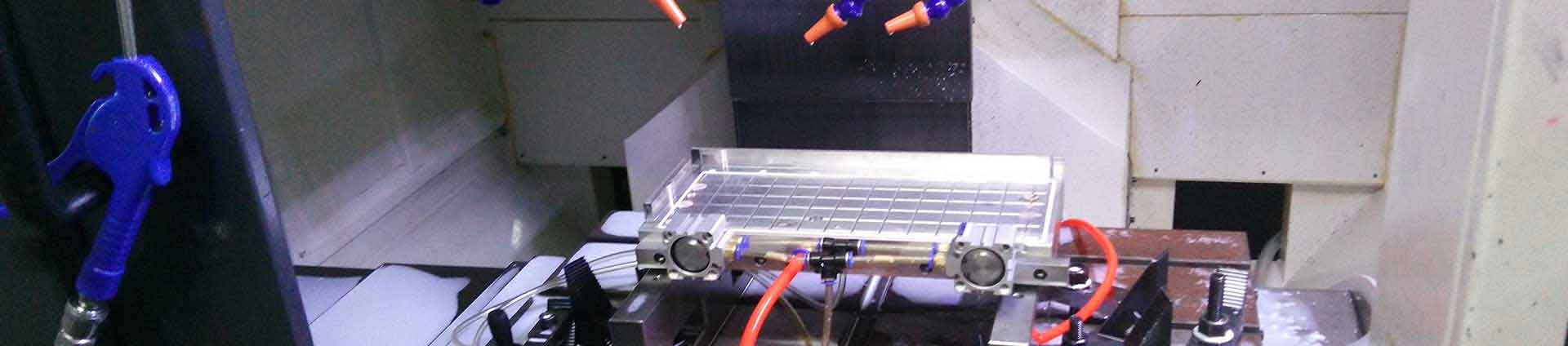

After analyzing the productivity factors, China Manufacturing Parts found that many units were adding to operational costs due to underutilized machining capabilities. Toolpath generation was detected as the weakest factor in the production chain. The VoluMill software is considered as a perfect replacement for traditional toolpath engines. The software helps increase machine utilization. China Manufacturing Parts tested the VoluMill by employing it for programming a difficult part in parallel to a popular CAD/CAM package. During the testing, it was found that the VoluMill outperformed the existing traditional models, and programmed the part in half the time like the CAD/CAM software.

China Manufacturing Parts utilized their oldest equipment to produce 304 stainless steel parts. The equipment was operated at the speed of 530 sfm to produce 10 parts within 13 minutes. By utilizing VoluMill, China Manufacturing Parts were able to reduce their costs by 35%. After this testing, China Manufacturing Parts submitted the adjusted bid. This time the bid received an approval, and the contract was renewed. The VoluMill engagement helped China Manufacturing Parts reduce their cycle times by 50% and programming time by 33%. The software also helped increase the tool life. For more information about the toolpath improvement and improving machining capabilities, as well as the manufacturing services provided, please contact China Manufacturing Parts Manufacturing directly.

inquiry@chinamanufacturingparts.com

inquiry@chinamanufacturingparts.com